Decarbonizing the steel industry,

zero direct emissions at no extra cost.

Decarbonizing the steel industry,

zero direct emissions at no extra cost.

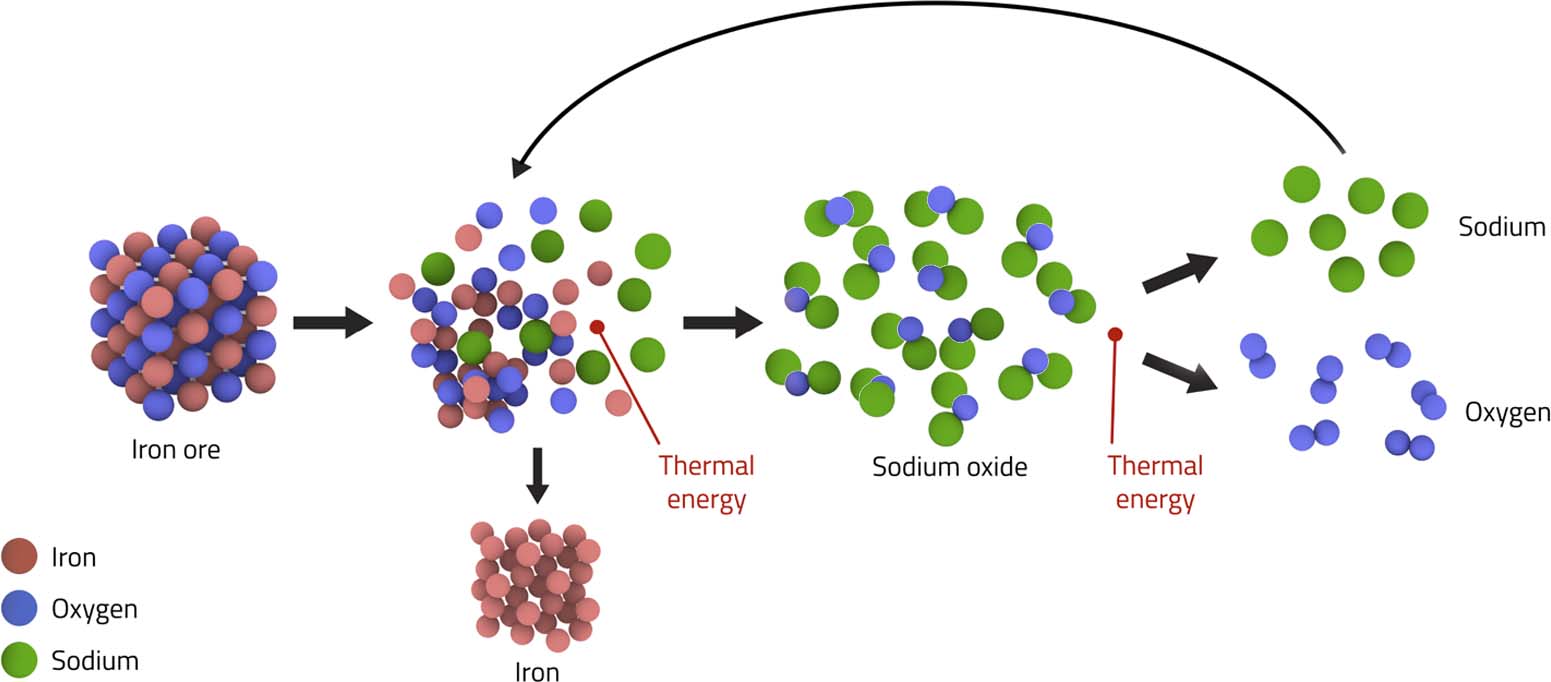

The Helios Cycle

Helios technology is based on sodium as the reducing agent, a two-step process in which sodium is used to reduce first row transition metals (like Iron), and in the second step, the byproduct sodium oxides are dissociated to reclaim the sodium in metal form and keep it in a closed loop within the system.

The required input is iron ore and heat, the output is iron and oxygen.

Helios does not require steelmakers to alter their energy infrastructure, as the Helios technology can be integrated into their existing infrastructure, which reduces cost and facilitates faster adoption.

Technological advantages

No direct carbon emissions

The Helios Cycle emits only oxygen as a byproduct, if a renewable energy source is used, the whole process is 100% carbon emissions-free.

lower energy consumption

Current iron production methods are conducted at 1200°C to 2000°C, The Helios Cycle is conducted between 400°C to 700°C, the process uses 50% less energy which will contribute to at least 20% reduction of production costs.

Compatible with low grade ores

The Helios Cycle can be used with low grade ores which today are mostly unusable, this opens the market to cheaper ore which in turn reduces further the final cost of the iron that is being produced.

No hydrogen

Using hydrogen requires special infrastructure to be built near the plant and the production of green hydrogen dramatically increases the cost of steelmaking.

No electrolysis

Powering electrochemical processes to produce iron uses more energy than current methods which raises production costs. The Helios Cycle uses only thermal energy which is why the overall energy consumption is lower than other green methods.

The Helios Cycle

Helios technology is based on sodium as the reducing agent, a two-step process in which sodium is used to reduce first row transition metals (like Iron), and in the second step, the byproduct sodium oxides are dissociated to reclaim the sodium in metal form and keep it in a closed loop within the system.

The required input is iron ore and heat, the output is iron and oxygen.

Helios does not require steelmakers to alter their energy infrastructure, as the Helios technology can be integrated into their existing infrastructure, which reduces cost and facilitates faster adoption.

Technological advantages

No direct carbon emissions

The Helios Cycle emits only oxygen as a byproduct, if a renewable energy source is used, the whole process is 100% carbon emissions-free.

lower energy consumption

Current iron production methods are conducted at 1200°C to 2000°C, The Helios Cycle is conducted between 400°C to 700°C, the process uses 50% less energy which will contribute to at least 20% reduction of production costs.

Compatible with low grade ores

The Helios Cycle can be used with low grade ores which today are mostly unusable, this opens the market to cheaper ore which in turn reduces further the final cost of the iron that is being produced.

No hydrogen

Using hydrogen requires special infrastructure to be built near the plant and the production of green hydrogen dramatically increases the cost of steelmaking.

No electrolysis

Powering electrochemical processes to produce iron uses more energy than current methods which raises production costs. The Helios Cycle uses only thermal energy which is why the overall energy consumption is lower than other green methods.

The green future of refining elements

Helios chose to focus on the iron industry due to the amount of energy it uses, and the negative impact current methods have on the environment. Helios refinement technologies is applicable to other elements, as well. Resource extraction could be done in a way that is far less harmful to the planet, not just iron, but silicon, copper, nickel, lithium and other critical materials.

The green future of refining elements

Helios chose to focus on the iron industry due to the amount of energy it uses, and the negative impact current methods have on the environment. Helios refinement technologies is applicable to other elements, as well. Resource extraction could be done in a way that is far less harmful to the planet, not just iron, but silicon, copper, nickel, lithium and other critical materials.

Helios Project Ltd © 2023